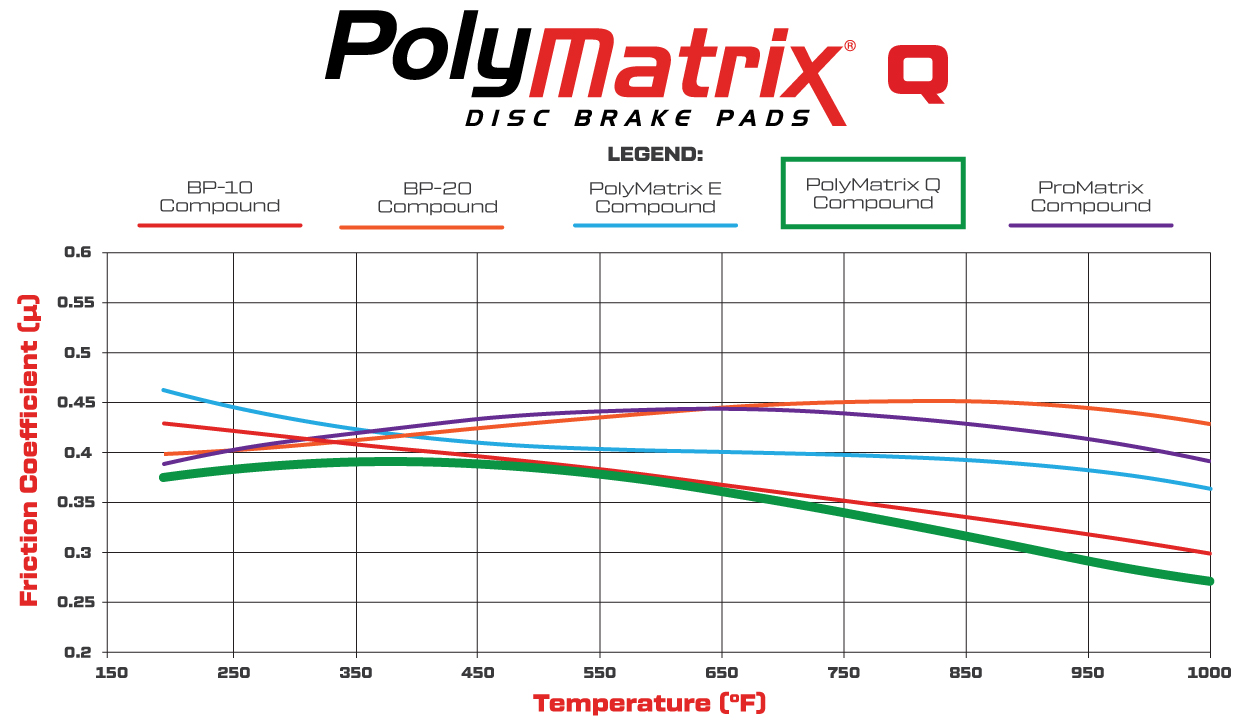

PolyMatrix Q Friction Coefficient and Temperature Values

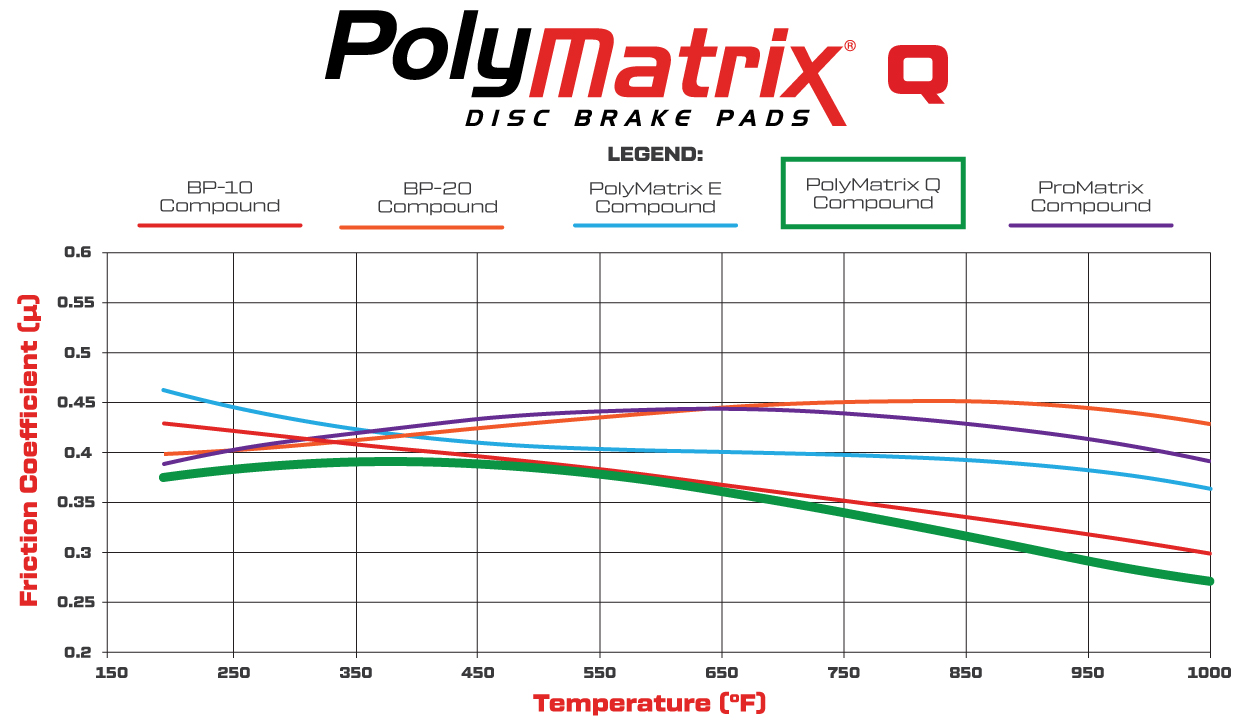

PolyMatrix Q Friction Coefficient and Temperature Values

Click Image to Close

The above friction data (μ) was recorded through braking cycles from 95 mph to 40 mph at a 0.5g deceleration.

Snubs were consecutively done until rotor temperature reached 1300°F. This graph represents average data and is for general trend visualisations only comparing Wilwood pads.

Chart data should not be used in comparison with other manufacturer's data. Test conditions, variables, and environment can affect test results.

Temperature range and overall friction value are the primary considerations for pad selection.

The pads must maintain the proper amount of friction for stopping power within the temperatures that will be realized on the track. Overall wear rate must also be considered.

For most asphalt and road race applications, compounds in the high-temperature range over 1000°F are usually necessary. Dirt track, drag race, and street performance applications usually operate at temperatures between 500° and 1000°F.

Keep in mind that these are general ranges and not absolute values. Many factors and unforeseen influences can affect brake temperatures.

The best indicator for pad selection will always be on-track performance.

If pad fade (friction loss) due to overheating occurs, improved cooling, a heavier rotor, or a higher temperature range pad may become necessary.